Jan 8, 2024 | news

Complete auto bearing kits offer a comprehensive solution for replacing worn-out wheel bearings, clutch bearings, and suspension parts in Korean cars, including popular brands like Hyundai, Kia, and SsangYong. These kits provide a convenient and cost-effective way to maintain optimal performance and safety.

Benefits of Complete Auto Bearing Kits

Matched Components: Complete bearing kits contain high-quality, matched components that are designed to work seamlessly together, ensuring proper fitment and reliable operation.

Easy Installation: Pre-configured kits simplify the installation process, reducing labor time and potential errors.

Extended Lifespan: Reputable brands like FAG, SKF, National, and ZKL provide bearings that meet or exceed OEM specifications, ensuring equal or better lifespan compared to original parts.

Cost-Effectiveness: Aftermarket korean car auto bearing kit offer competitive prices while maintaining high-quality standards, making them a cost-effective alternative to genuine OEM kits.

Enhanced Performance: Replacing worn-out bearings with new ones reduces friction, improves steering response, decreases noise, and enhances overall stability.

Elantra Auto Wheel Front Bearing Kit

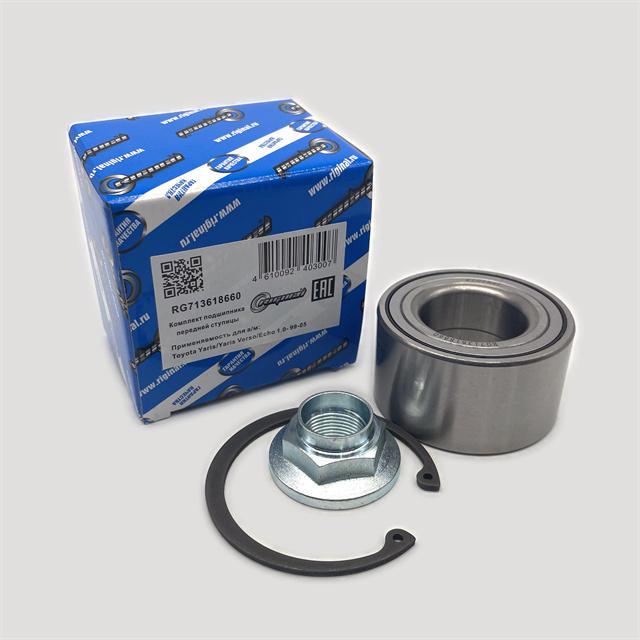

The front wheel bearings of Hyundai Elantra typically require replacement every 60,000 to 100,000 kilometers, depending on driving conditions. Complete Elantra front wheel bearing kits include both inner and outer wheel bearings, races, seals, dust covers, and washers. Replacing both bearings simultaneously is recommended as they tend to wear together.

Benefits of Elantra Wheel Bearing Kits

Comprehensive Kit: Elantra wheel bearing kits provide all the necessary components to replace old bearings and components in one go, ensuring proper fitment and easy installation.

Simplified Installation: With clear instructions included, the replacement process typically takes 2 to 3 hours, making it a manageable DIY project for car enthusiasts.

Long-Lasting Performance: Genuine Hyundai kits and high-quality aftermarket kits can last for 80,000 to 120,000 kilometers when installed correctly.

Improved Handling: Replacing worn-out wheel bearings significantly improves steering response, reduces noise, and enhances overall stability, leading to a more enjoyable driving experience.

By investing in complete auto bearing kits, Korean car owners can ensure smooth performance, safety, and cost-effectiveness, maintaining their vehicles in optimal condition for a pleasurable driving experience.

Jan 2, 2024 | news

In the complex world of heavy-duty industrial machinery, the term “Shock Support Bearings” might sound technical and niche, yet their significance in ensuring smooth operations and enhancing equipment longevity cannot be overlooked. These crucial components play a pivotal role in mitigating vibrations, absorbing shocks, and maintaining stability within a wide array of heavy machinery, contributing significantly to their performance and reliability.

Understanding Shock Support Bearings:

Shock Support Bearings, also known as shock absorber bearings or vibration isolation bearings, are specialized components designed to dampen and absorb shocks, vibrations, and impacts within machinery. They are engineered using materials like rubber, elastomers, or other resilient substances that possess excellent shock-absorbing properties.

Functions and Significance:

1. Vibration Dampening: One of the primary functions of shock support bearings is to absorb and reduce vibrations generated during the operation of heavy machinery. This dampening effect helps prevent excessive oscillation, ensuring a smoother and more stable functioning of the equipment.

2. Shock Absorption: In environments where machinery encounters sudden shocks or impacts, such as uneven terrains or heavy load handling, these bearings absorb and dissipate the shock, protecting the machinery from potential damage.

3. Noise Reduction: By minimizing vibrations and impacts, shock support bearings also contribute to reducing noise levels generated by machinery, creating a quieter and more comfortable working environment.

4. Equipment Longevity: These bearings play a crucial role in prolonging the lifespan of machinery by mitigating the stress and strain caused by vibrations and shocks, thereby reducing wear and tear on other components.

Types of Shock Support Bearings:

Various types of shock support bearings are engineered to suit diverse industrial applications:

1.Rubber-Metal Isolators: These consist of a rubber component bonded to metal plates or mounts, providing effective vibration isolation while offering durability and stability.

2. Spring-Mounted Bearings: Utilizing springs or elastomeric elements, these bearings provide both shock absorption and vibration isolation, ideal for heavy machinery subjected to variable loads.

3. Pneumatic Dampers: Employing air or gas chambers, pneumatic dampers offer adjustable shock absorption capabilities, allowing for fine-tuning according to specific operational requirements.

Maintenance and Replacement:

Regular inspection and maintenance of shock support bearings are essential to ensure optimal performance and longevity of industrial machinery. Monitoring for signs of wear, tear, or loss of elasticity is crucial. Timely replacement with high-quality, compatible bearings is necessary when wear or deterioration is observed to prevent further damage to the machinery.

In the intricate landscape of heavy industrial machinery, Shock Support Bearing stand as guardians against vibrations, shocks, and excessive noise, ensuring smoother operations and safeguarding equipment integrity. Understanding their role, employing proper maintenance practices, and utilizing high-quality bearings tailored to specific machinery are crucial steps towards maximizing efficiency, minimizing downtime, and prolonging the lifespan of these powerful machines.

Dec 25, 2023 | news

Lada cars have earned a reputation for durability and reliability, but like any vehicle, they require proper maintenance to ensure their components remain in good working condition. The clutch assembly and shock absorbers are two critical systems that can significantly impact the performance and safety of your Lada if not adequately maintained.

Clutch Assembly: Ensuring Smooth Power Transmission

Lada Shock-absorbing support bearing consists of several key components, including the clutch disc, pressure plate, release bearing, and clutch slave cylinder. The clutch disc and pressure plate utilize friction material to engage and disengage engine power from the transmission, while the release bearing facilitates the movement of the clutch fork to disengage the clutch. All these components rely on bearings that require regular inspection and maintenance.

Worn or damaged clutch assembly bearings can lead to clutch slippage, excessive noise, vibrations, and premature clutch wear. To prevent these issues, it is crucial to ensure proper lubrication and conduct regular inspections of the release bearing and pilot bearing. If necessary, replace worn clutch assembly bearings with genuine Lada bearings designed for a perfect fit and extended service life.

Shock Absorbers: Enhancing Ride Comfort and Safety

Shock absorbers play a vital role in Lada’s suspension system, utilizing rubber bushings and bearings to mitigate shock loads from the road. The shock-absorbing support bearings maintain proper alignment of the shock absorber and suspension components. However, these bearings can deteriorate over time due to wear, corrosion, and contamination.

Worn shock-absorbing support bearings can result in excessive noise, vibrations, and reduced shock absorption performance. Regular inspection of these bearings for damage, cracks, and corrosion is essential. If any issues are identified, replace the worn bearings with high-quality aftermarket or genuine Lada parts to restore optimal shock absorption and ride comfort.

Ensuring Peak Performance and Longevity

To keep your Lada performing at its best, it is recommended to have the clutch assembly and suspension checked during scheduled maintenance intervals. Proper lubrication of all moving components and timely replacement of worn bearings are crucial for ensuring smooth operation and preventing costly repairs. By using genuine Lada parts for these high-stressed components, you can be confident in achieving optimum performance and durability. With proper care and maintenance, your Lada’s clutch and suspension systems will provide years of trouble-free motoring.

Dec 18, 2023 | news

Tensioner pulley bearings are indispensable components in VAZ vehicles, contributing to the proper operation and longevity of the drive belt system. By maintaining the correct tension in the drive belt, these bearings enable the efficient functioning of essential auxiliary systems. Regular maintenance, including inspections and replacements, is crucial to identifying and addressing any tensioner pulley bearing issues promptly.

The Role of Tensioner Pulley Bearings

Tensioner pulley bearing VAZ are responsible for maintaining the correct tension in the drive belt system of VAZ vehicles. The drive belt, also known as the serpentine belt, connects various components of the engine, transmitting power and enabling their operation. The tensioner pulley, equipped with a bearing, is designed to apply the necessary tension to the drive belt, keeping it securely in place and ensuring optimal power transmission.

Ensuring Proper Belt Tension

A properly tensioned drive belt is crucial for the efficient functioning of auxiliary systems in VAZ vehicles. The tensioner pulley bearing plays a key role in maintaining the appropriate tension throughout the belt’s operation. By applying the right amount of pressure, the tensioner pulley bearing prevents belt slippage, excessive vibrations, and potential damage to the drive belt and associated components. This ensures the smooth operation of systems such as the alternator, power steering, and air conditioning, contributing to the overall performance and reliability of the vehicle.

Common Issues and Symptoms

Over time, tensioner pulley bearings in VAZ vehicles may experience wear and tear, leading to various issues. One common problem is bearing failure, resulting in noise, excessive play, or complete seizing of the pulley. A damaged or faulty tensioner pulley bearing can cause the drive belt to become loose or misaligned, leading to belt squealing, decreased performance of auxiliary systems, and potential belt failure. It is important to pay attention to warning signs such as unusual noises or belt slippage, as these indicate potential tensioner pulley bearing issues.

Importance of Regular Maintenance

Proactive maintenance is crucial to ensuring the longevity and optimal performance of tensioner pulley bearings in VAZ vehicles. Regular inspections and scheduled replacements, as recommended by the vehicle manufacturer, can help identify and address any potential issues before they escalate. Routine maintenance should include visual inspections of the tensioner pulley bearing for signs of wear, damage, or excessive play. Lubrication of the bearing may also be necessary, depending on the specific design and recommendations.

Genuine Parts and Professional Repairs

When it comes to tensioner pulley bearings in VAZ vehicles, it is essential to use genuine parts and rely on professional repairs. Genuine parts ensure compatibility, reliability, and durability, providing the best performance and longevity. Professional technicians have the expertise and knowledge to diagnose and address tensioner pulley bearing issues accurately. They can ensure precise installation, proper tension adjustment, and comprehensive testing to verify the correct functioning of the drive belt system.

Dec 12, 2023 | news

High-quality ball bearings from China high quality ball bearing exporter, are indispensable components that enable smooth, efficient, and reliable motion in various applications. Their precision design, reduced friction, high load capacity, and durability make them vital for enhancing performance and efficiency.

Understanding High-Quality Ball Bearings

High-quality ball bearings are mechanical devices that facilitate smooth and precise rotational motion by minimizing friction between moving parts. They consist of an outer ring, an inner ring, a cage, and a set of steel balls. Here are some key aspects to understand about high-quality ball bearings:

a. Design and Construction: High-quality ball bearings are precision-engineered with meticulous attention to detail. They are typically designed with specific load capacities, speed limits, and operating conditions in mind. The rings are typically made of high-grade steel, while the balls are crafted from hardened steel or ceramic materials.

b. Rolling Element: The rolling element in ball bearings consists of steel balls that are evenly spaced and held in place by a cage. The number and size of balls vary depending on the bearing’s design and intended application. The rolling action of the balls reduces friction, allowing for smooth and efficient rotational motion.

c. Types of Ball Bearings: There are various types of ball bearings available, including deep groove ball bearings, angular contact ball bearings, thrust ball bearings, and self-aligning ball bearings. Each type is designed to accommodate specific load types and operating conditions.

d. Lubrication: Proper lubrication is crucial for the smooth operation and longevity of ball bearings. Lubricants reduce friction and wear between the rolling elements and raceways, ensuring optimal performance and preventing premature failure. Common lubrication methods include grease and oil lubrication.

Benefits of High-Quality Ball Bearings

High-quality ball bearings offer numerous benefits that contribute to improved performance, increased durability, and enhanced efficiency in various applications. Here are some key advantages:

a. Reduced Friction: Ball bearings help minimize friction between rotating parts, allowing for smoother and more efficient motion. By reducing friction, they help conserve energy, reduce wear, and increase the lifespan of machinery and equipment.

b. High Load Capacity: High-quality ball bearings are designed to withstand high loads and provide exceptional load-carrying capacity. They distribute the load evenly across the rolling elements, ensuring reliable performance even under heavy loads.

c. Precision and Accuracy: Ball bearings offer precise and accurate rotational motion, resulting in smooth and consistent performance. Their design allows for minimal play or movement, ensuring precise positioning and alignment of components.

d. Speed and Efficiency: Ball bearings enable high-speed operations with minimal heat generation. Their low friction characteristics and optimized design contribute to efficient power transmission, reducing energy consumption and improving overall efficiency.

e. Durability and Longevity: High-quality ball bearings are engineered to withstand demanding operating conditions, including high temperatures, shock, and vibration. They are built to last, minimizing downtime and maintenance costs.

Applications of High-Quality Ball Bearings

High-quality ball bearings find extensive applications in a wide range of industries and machinery. Here are some common areas where they are utilized:

a. Automotive Industry: Ball bearings are essential components in vehicles, used in engines, transmissions, wheel hubs, and suspension systems. They enable smooth and efficient rotation, contributing to overall vehicle performance and reliability.

b. Industrial Machinery: Ball bearings are widely used in industrial machinery such as pumps, compressors, electric motors, and conveyors. They facilitate smooth and precise motion, ensuring optimal performance and productivity.

c. Aerospace and Aviation: High-quality ball bearings are critical in the aerospace and aviation industries, where precision, reliability, and durability are paramount. They are used in aircraft engines, landing gear systems, control mechanisms, and various other applications.

d. Robotics and Automation: Ball bearings play a vital role in robotics and automation, enabling precise and efficient motion control. They are employed in robotic arms, CNC machines, linear actuators, and other automated systems.

e. Power Generation: Ball bearings are utilized in power generation equipment such as wind turbines, hydroelectric generators, and gas turbines. They help reduce friction and ensure smooth rotation, maximizing power output and efficiency.

Choosing High-Quality Ball Bearings

When selecting high-quality ball bearings for your specific application, several factors should be considered:

a. Load and Speed Requirements: Determine the load capacity and speed requirements of your application. Choose ball bearings that can withstand the anticipated loads and operate within the required speed limits.

b. Application-Specific Considerations: Consider the specific operating conditions of your application, such as temperature, vibrationlevels, and environmental factors. Select ball bearings that are designed to perform optimally under these conditions.

c. Quality and Reliability: Ensure that the ball bearings you choose are manufactured by reputable manufacturers known for their high-quality products. Look for certifications and standards compliance to ensure reliability and longevity.

d. Lubrication and Maintenance: Consider the lubrication requirements and maintenance procedures associated with the ball bearings. Opt for bearings that offer easy lubrication and require minimal maintenance.

e. Cost-Effectiveness: While high-quality ball bearings may come at a higher initial cost, they offer long-term benefits in terms of performance, durability, and reduced downtime. Consider the overall cost-effectiveness of the bearings for your application.